CBM Rules

CBM Rules are configured independently for each Quality Preference Profile to define if any CBM Alert Action rules need to be triggered when Test responses result in an overall Warning or Fail state. These rules are evaluated based on the Quality Preference Profile as different Alert Actions may be required for the same Test or Spec used on a different Preference Profile. CBM Rules can be configured on the Parent Spec and/or Child Tests. When Tests are attached to a Work Order they retain references to the Quality Preference Profile key (Address Number, Customer Group, Item Number & Item Group) even if they are attached to the Work Order manually.

This guide only covers the setup steps required for Condition Assessment. Setup of Condition Based Maintenance itself is covered within our CAM Setup Documentation guide as well as within standard JDE documentation for the Asset Lifecycle Management - Condition-Based Maintenance Implementation Guide.

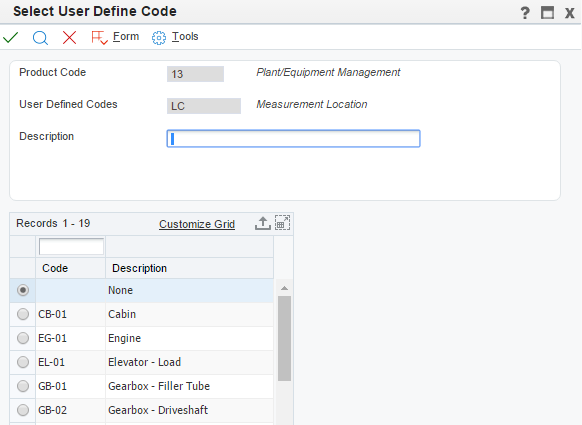

To complete the setup at least one Measurement Location must be defined.

Measurement Locations are defined in UDC 13/LC. Blank can be configured as a valid value if only a generic measurement location is applicable.

Note that it is advisable to utilize measurement locations properly as this gives you much more control over the detail of the condition-based actions i.e. whether to create a notification versus raise a Work Order. Without the measurement location being specific it is hard to get enough level of detail to distinguish the type of test that has failed in order to create a specific work order for the maintenance task that needs to be completed.

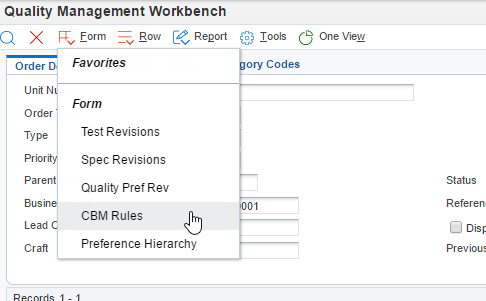

From the Quality Management Workbench take the CBM Rules Form Exit

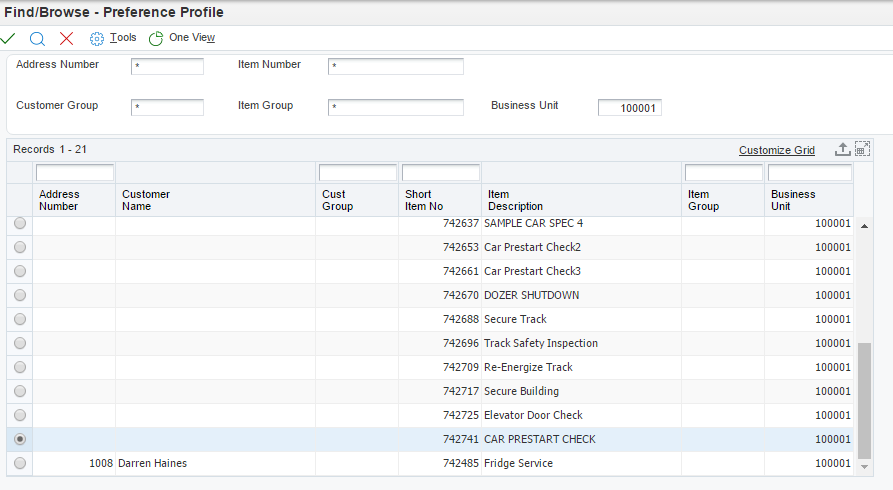

CBM Rules are setup and apply to a given Preference Profile.

Locate the Preference Profile that you wish to setup CBM alerts for and press OK/Select

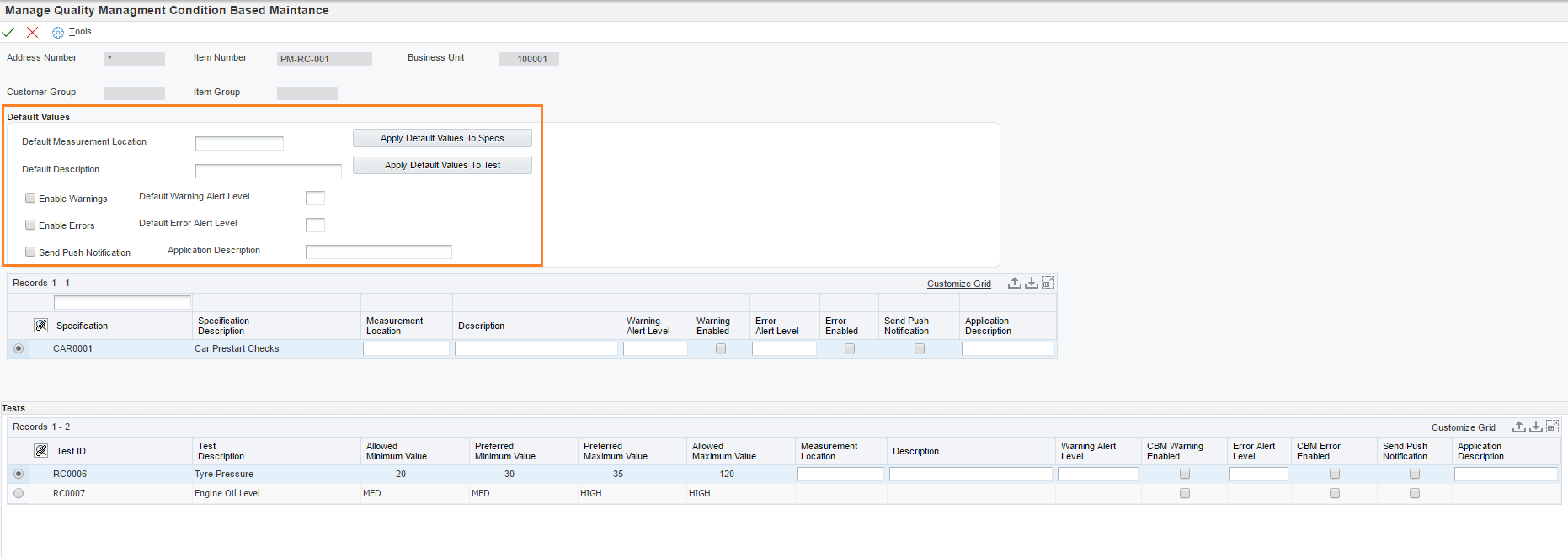

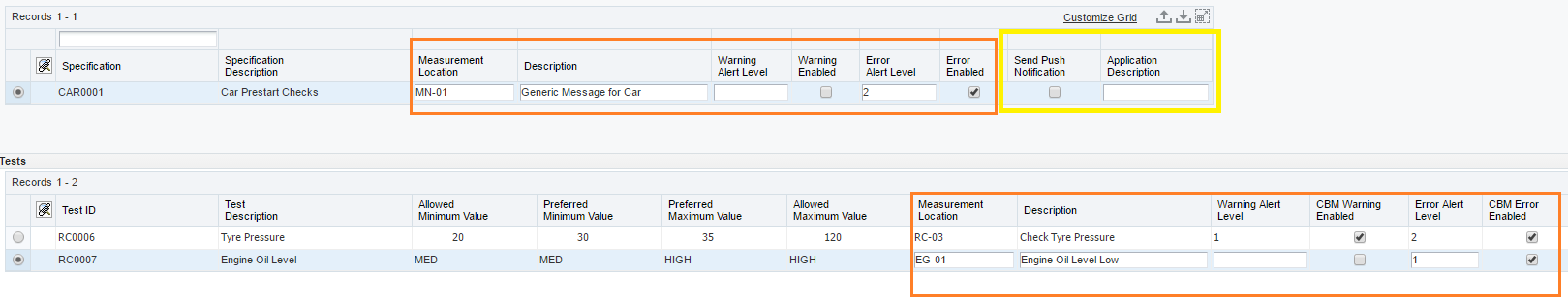

The CBM setup screen has an upper “Default Values” section that can be used to push a set of values out to both Specs and to Tests if only a generic set is required. Otherwise, you can enter directly into each line as required.

Detailed Entry

The “Send Push Notification” and “Application Description” fields can be ignored.

These fields are provided for where a mobile application is receiving an alert via Push Notification.

Alert Logic

Alerts can be setup as a combination of both Spec and Test alerts.

The Spec will alert whenever ANY of the tests beneath it are in Warning or Error state dependent on the levels selected.

A test will alert only where the specific test is in an overall Warning or Failure state.

Required Fields

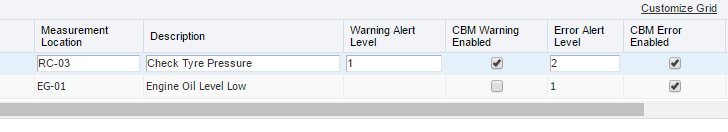

Measurement Location: The measurement location can be used in Combination with the Unit/Site/Customer etc. to trigger a specific action, this is particular of use when setting alerts at the test level where for instance if the Engine Oil Level is low we may want to trigger an engine service to be completed but we don’t want to trigger an engine service if the tyre pressure is low.

Description: The description here is written to the CBM alert message, so for instance the user may receive an email with “Check Tyre Pressure”.

Warning Enabled, Error Enabled (Tick Boxes): Warning refers to an overall Test Warning Result and Error refers to an overall Test Failure. So, if the test has failed a message will be triggered for the alert level that has been set in the corresponding alert level fields.

Warning Alert Level, Error Alert Level: The Warning/Error alert level refers to the levels that have been setup. Alert Level 1 is “Warning” and Alert Level 2 is “Alarm”

This standard JDE functionality gives greater flexibility when determining the action to handle the particular alert.

Example:

In this example the Engine Oil Level test has Error Alert Level set to “1’ this means that if the test Fails then this will just trigger a warning message rather than an Alarm message. However, we might have other engine tests where a particular result indicates an imminent failure where a failed test result should trigger an Alarm state (which could then trigger a subsequent Work Order as well as notification emails etc.)